When producing automotive components that require a high level of precision and multiple cavities, it is necessary to make use of complex tooling. However, automation by itself was not enough to increase capacity within the cell because on-machine measurement within the cell created a bottleneck. This prevented the cmm inspection services from reaching its full potential. As a direct result of the business's decision to integrate a CMM into the automated cell, the corporation was able to completely clear the queue of work that had accumulated in the tooling department, which had been an ongoing problem for some time. In the early days of the company, it was a division of Briggs and Stratton, which dates back more than a century. In modern times, however, it is known by the name Strattec, and it is in the business of designing, developing, manufacturing, and marketing mechanical locks, electronically enhanced locks and keys, as well as ignition lock housings. In order to successfully produce these intricate parts, the manufacturing facility needed to undergo some necessary upgrades. having a professional connection with Premier Machine Tool Midwest, which is found in the city of Hartland in Wisconsin. This automation solution travels along a rail in order to feed multiple machines.

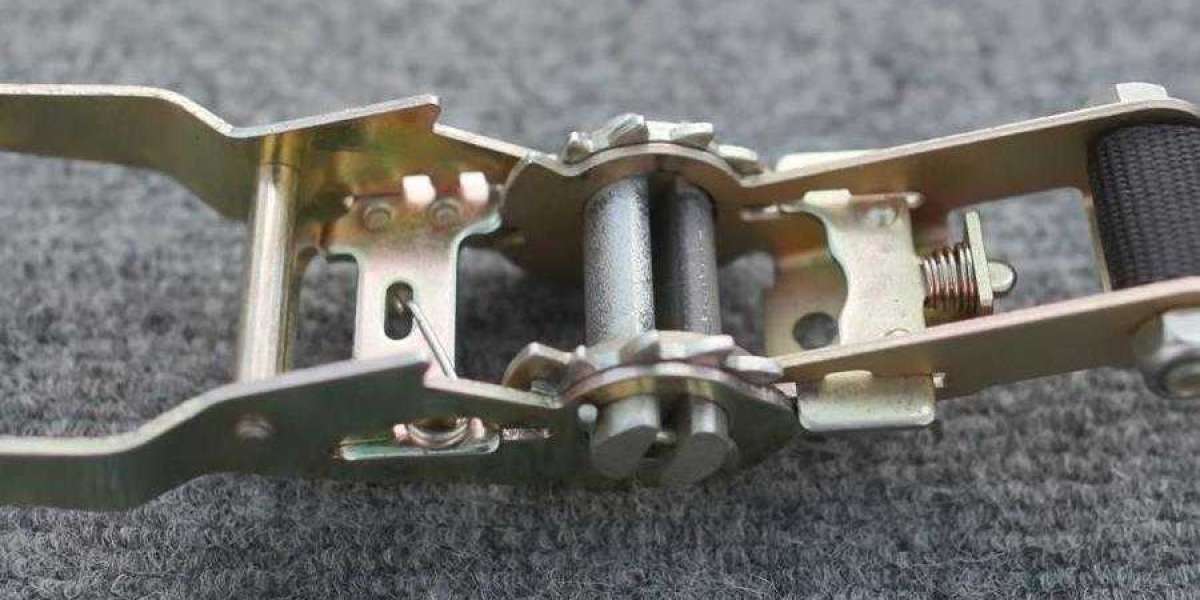

It also makes use of the company's WorkShopManager software, which combines all of the machining and measuring processes into a single workflow. After some lapse of time, a Makino U32J wire EDM was installed where it was supposed to be. The structure was designed to operate continuously, despite having no lights on at any time of the day or night. In spite of this, Strattec was unhappy with the length of time needed to complete a batch once the machine had reached its maximum level of functionality. Instead of actually machining the component, the CNC machines were assigned the task of locating it, and the operators spent a significant portion of their days preparing the parts to be run overnight. The business made the decision to alleviate the bottleneck and improve the inspection quality by installing a Brown Sharpe One shopfloor coordinate measuring machine (CMM) made by Hexagon Metrology (North Kingstown, Rhode Island). It does this before each pass through the machine in order to fulfill its primary function, which is to locate electrodes and workpieces on their respective pallets in preparation for feeding them to the EDMs. Because of how dirty it is, cmm inspection services the CMM will not be able to inspect it until it has been cleaned.

During the cleaning process, both the lubrication and the dirt will be removed. After that, the part is moved by the robot to the coordinate measuring machine (CMM) so that the necessary compensation for spark gaps as well as the offsets for the X, Y, Z, and C (rotation in the X-Y plane) coordinates on electrodes can be determined. Workpieces are evaluated so that their X, Y, Z, and C offsets can be calculated. After it has been completed, it is brought back to the CMM so that it can be checked for quality. The data that is collected by the CMM is then imported into PC-DMIS, which is Hexagon Metrology's flagship piece of software. PC-DMIS provides users with access to a comprehensive library of macros that have been made with the die-making industry in mind. Offline toolset for electrodes take into account the true burning geometry of the electrode rather than relying on the witness measurement, which is taken at the base of the electrode. The witness measurement is taken at the center of the electrode. These intricate measurements can be finished in a matter of minutes with a degree of precision that is superior to that which can be achieved using the traditional witness method of inspection.

The method in question is the method of inspection that is most commonly used. No longer is it necessary to measure electrodes on a sinking machine, which is a process that is both laborious and time-consuming. This step in the programming process has been eliminated. After the CMM was installed, the same batch of electrodes could be inspected at a rate that is at least fifty percent faster than it was before, and this could happen even while the EDM was working on other components. In addition to this benefit, the current method of toolmaking does away with the requirement for any kind of manual intervention in the process of data entry. The company claims that as a result of the recent improvements in quality, the tooling department is now in a position to determine whether or not electrodes are of sufficient quality before sinking them into the steel. Additionally, due to the accuracy of a CMM, each component that is removed from the cmm inspection services is inspected with greater precision, and the presence of the operator is not necessary for the inspection to take place.

Because CMM was integrated into our system, we have gained back even more time, which is probably between 30 and 40 percent of the total. Because we had already put in place our Brown Sharpe One CMM, we were able to offer everyone else higher levels of productivity than they had previously experienced. Craig Broetzmann, who is in charge of the CNC team at Strattec, asserts that he is positive that the accomplishment in question could not have been accomplished if the cmm inspection services had not been configured in the manner in which it is at the present time. He claims that in the past, when we had a rush job, we were required to stop everything and shift our focus to that project. In today's world, we have the ability to more effectively prioritize the work that we do. The tasks that needed anywhere from two to four days to complete in the past can now typically be finished in a single day. The team can make adjustments to the instrument and then resample almost instantly because they are not required to wait for a response from another department. Additional opportunities to investigate have become available at the facility as a result of the automated cell.