The term "Industrial Internet of Things" is well-known in the manufacturing industry, and the Industrial Internet has gradually emerged as a critical link in the realization of smart factories and smart manufacturing, demonstrating the significance of the Industrial Internet of Things.

The question of how to deploy and build the Industrial Internet of Things has evolved into a problem that every processing company must take into consideration. What follows is a step-by-step guide on how to set up the Industrial Internet of Things.

What is injection molding manufacturers about the Industrial Internet of Things that is so popular today? Its real advantage, however, is not in system upgrades, but rather in continuously improving efficiency through the development of constant data and the provision of necessary information for industrial Internet of Things strategies. In order to facilitate the development of the Industrial Internet of Things. As a first step, we should do the following:

1. Identify the desired outcome.

When deploying the Industrial Internet of Things, the primary goal is to reduce costs and increase efficiency, or to achieve remote monitoring of systems and processes. Once the target has been established, we can begin to analyze the components in light of the existing equipment and information.

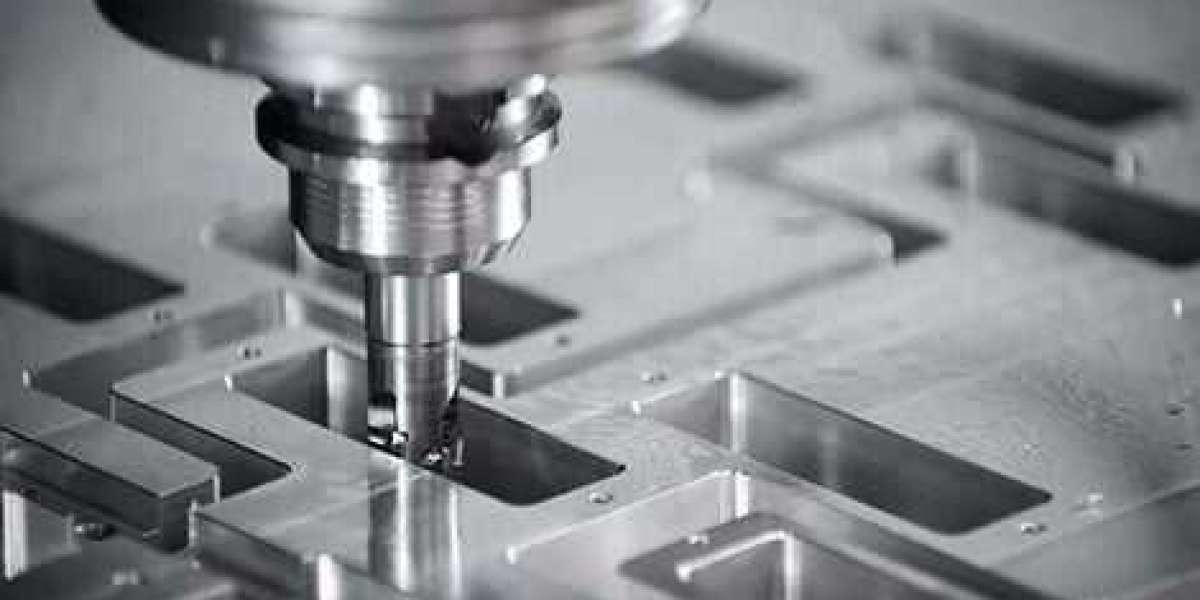

This is an extremely important procedure. In the majority of cases, it is not possible to completely replace the old equipment, and the cost would be prohibitively expensive. To make the most of their existing equipment, Steel CNC machining companies are increasingly inclined to integrate communication equipment and protocol conversion software in order to connect all systems and maximize their productivity.

2. The connection of the device

Because the Internet of Things is a "network," it must be connected in order to function. Because of this, companies must connect machines and sensors from a variety of different vendors to maximize efficiency. They can integrate sensors for processing into older equipment that lacks communication capabilities, and they can strategically re-arrange a sensor network to meet the data collection needs of a given application.

The device completes the connection and makes it possible for the devices to communicate with one another. It is also necessary to consider how to push the data. The true source of power for the Industrial Internet of Things and cloud computing is data centralization and integrated applications for extracting and processing information from data streams. Many industrial Internet of Things platforms now include databases with a variety of features, ranging from data storage and time processing to equipment supply and reporting. Despite the fact that they are typically configured for specific applications, many of them are designed to be simple and quick to implement.

3. Remove any snags or snags

Privacy and security are important barriers to investment in the Industrial Internet of Things, and they are important barriers to investment in the Industrial Internet of Things. When collecting and transmitting sensitive data, it is necessary to ensure that it is protected. As a result, the Industrial Internet of Things must implement special security measures to ensure that data can be collected, monitored, processed, and stored in a secure manner. However, in order to ensure security, it is necessary to strike a balance between time and resource-related costs as well as data protection.