In the realm of machinery maintenance, bearing cross reference and bearing chart play pivotal roles in ensuring smooth operations and prolonged equipment lifespan. Bearings, the unsung heroes of machinery, support rotating shafts and reduce friction, thus enabling efficient mechanical movement. However, identifying the right bearing for replacement or maintenance purposes can be a daunting task, especially when dealing with diverse brands and models. This is where a comprehensive bearing chart becomes indispensable.

Understanding Bearing Cross Reference

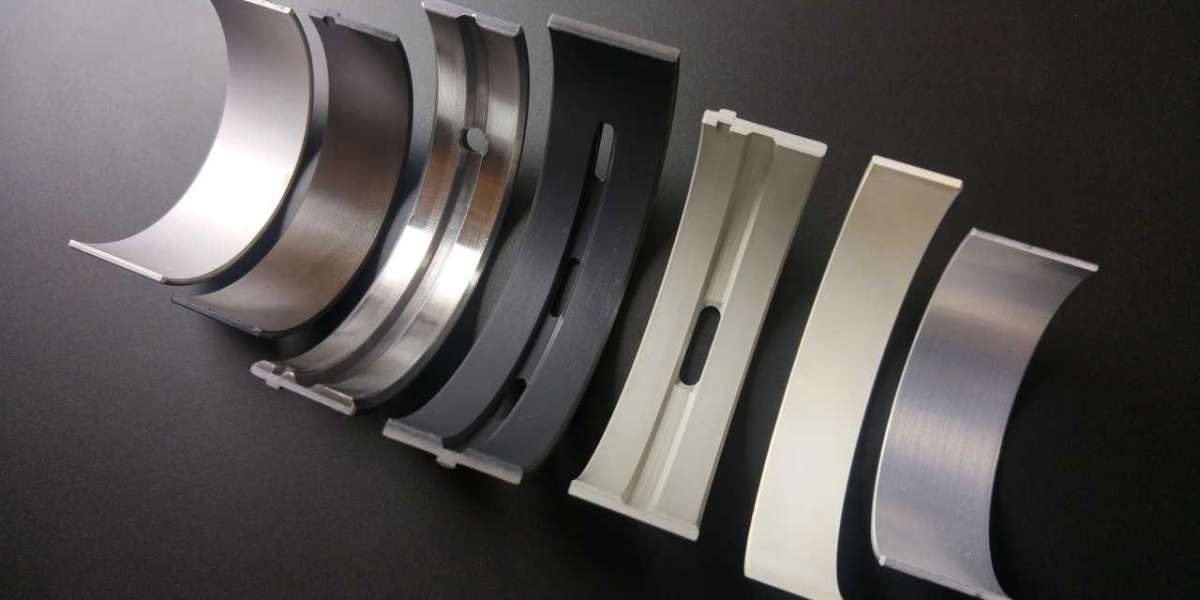

One of the primary challenges in equipment maintenance is finding the exact replacement part, especially when dealing with bearings. Bearings come in various shapes, sizes, and specifications, and different manufacturers often assign unique part numbers to their products. This is where bearing cross reference comes into play. A bearing cross reference is essentially a tool that allows users to match the part numbers of bearings from different brands, making it easier to find suitable replacements. By using a bearing chart, maintenance professionals can quickly identify equivalent bearings across multiple brands, thereby streamlining the procurement process and minimizing downtime.

Utilizing a Bearing Chart for Maintenance Efficiency

Imagine a scenario where a critical piece of machinery suddenly malfunctions due to a faulty bearing. In such situations, every minute of downtime translates to lost productivity and revenue. However, with access to a comprehensive bearing chart, maintenance teams can swiftly identify alternative bearings that are compatible with the equipment in question. Whether it's a ball bearing, roller bearing, or spherical bearing, a well-organized bearing chart provides valuable information such as dimensions, load capacities, and interchangeability, empowering maintenance personnel to make informed decisions and expedite repairs. Moreover, by standardizing the replacement process across different equipment types, organizations can streamline their maintenance protocols and achieve greater operational efficiency.

Conclusion

A bearing chart serves as an indispensable tool for equipment maintenance professionals seeking to streamline the procurement process and minimize downtime. By facilitating bearing cross reference, these charts enable swift identification of compatible replacement bearings from various brands, thereby ensuring uninterrupted operations and prolonging the lifespan of machinery. As industries continue to rely on complex machinery for their operations, investing in a robust bearing chart can significantly enhance maintenance efficiency and contribute to overall productivity and profitability. Embrace the power of bearing cross reference and unlock a world of possibilities in equipment maintenance today.